- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Lithium polymer battery Theory

2023-05-12

Lithium polymer battery Theory

2023-5-12

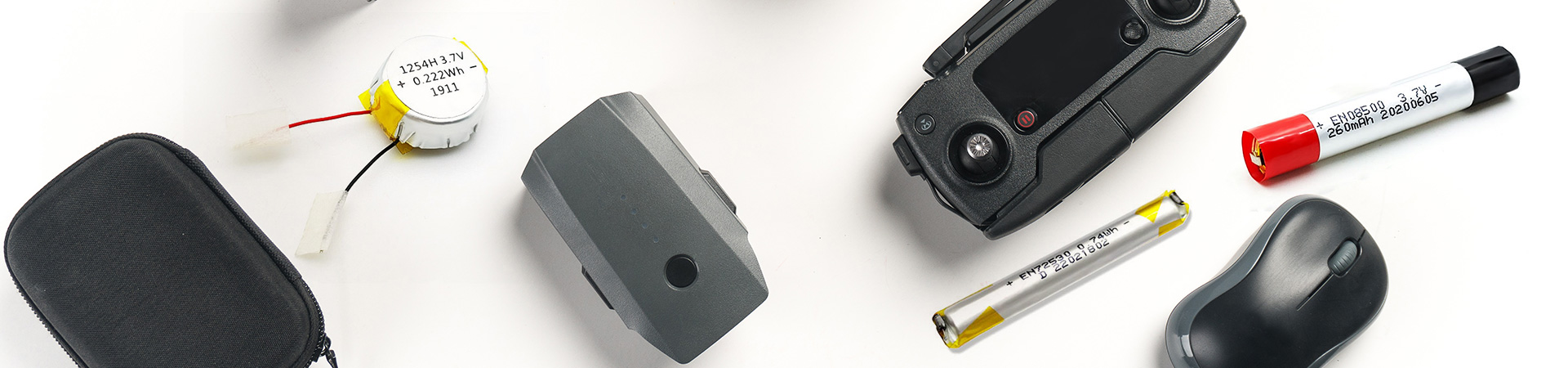

There are two commercially available technologies on the market collectively referred to as lithium-ion polymers (where "polymer" represents "electrolyte isolation polymer").

The battery consists of the following parts:

Positive electrode: LiCoO2 lithium cobalt dioxide or LiMn2O4 lithium tetraoxide manganese dioxide

Diaphragm: Conductive electrolyte polymer (such as polyethylene glycol, PEO)

Negative electrode: lithium or lithium carbon embedded (chemical) compound

Typical reaction: (discharge)

Negative electrode: (Carbon Lix) → C+xLi+xe

Diaphragm: Li conductive

Positive electrode: Li1 − xCoO2+xLi+xe → LiCoO2

Total reaction: (carbon xLi+xe)+Li1-xCoO2 → LiCoO2+carbon

Electrolyte/membrane polymers can be solid polymers, such as polyethylene glycol (PEO), lithium potassium hexafluoride (LiPF6), or other conductive salts with silica or other filling materials that enhance mechanical properties (such methods have not yet been commercialized). Under safety requirements, most batteries use carbon embedded lithium as the negative electrode, except for certain manufacturers such as Avestor (after merging with Battscap) who use metallic lithium as the negative electrode (referred to as lithium metal polymer batteries).

Both commercial batteries are polymerized with polyvinylidene fluoride (PVdF) by coating colloidal solvents and salts such as ethylene carbonate (EC)/dimethyl carbonate (DMC)/diethyl carbonate (DEC). The difference lies in the use of lithium manganese oxide (LiMn2O4) as the positive electrode (Bellcore/Telcordia's technology); The traditional method is to use cobalt lithium oxide (LiCoO2).

Although not yet widely available commercially, there are other different types of lithium polymer batteries that also use polymers as positive electrodes. For example, Moltech is developing positive electrodes made of conductive plastics and carbon sulfur compounds. However, as of 2005, this technology seemed to have issues with self release and production costs were also too high.

Other methods include using sulfur containing organic compounds and conductive polymers as positive electrodes, such as Polyaniline. This method can achieve good high discharge capacity, including low internal resistance and high discharge capacitance, but there are problems with insufficient cycle times and high cost.